The AME Center serves as an incubator for cross-disciplinary research involving researchers in the 3 core research areas, as well as faculty and scientists from Mechanical Engineering, Electrical and Computer Engineering, Civil and Environmental Engineering, and other STEM disciplines. An example of this synergy is the application of the mechatronic group's novel optimal adaptive control technology to problems in flow control, a specialty of the aero-propulsion group.

This Center of Excellence (COE) conducts fundamental research that transforms the way conventional distributed sensing, state estimation, morphing structures, and control are applied to high speed aerospace systems. Our team addresses the limitation of conventional feedback loops using novel sensing motifs and inherent coupling to adaptive structures to create an agile and robust aerospace system with integrated sense, assess and respond functionality. Our inter-disciplinary approach leverages diverse methodologies and team member expertise in information theory, physics-based models, reservoir computing, sensors for high speed environments, morphing structures, control and experimental aerodynamics to meet the goals of an integrated sense, assess and respond framework.

Applied Superconductivity Center (ASC) advances the science and technology of superconducting magnets, working from atomic scale fundamentals, through complex conductors to construction of the highest field superconducting magnets yet made. ASC has comprehensive laboratories for superconductor fabrication, superconducting property and microstructural evaluations, and magnet construction and testing.

The CEE Environmental Engineering Laboratory is equipped to carry out fundamental and applied research on water treatment, landfilling, resource recovery, and bioremediation. Key equipment includes:

- A gas chromatography-mass spectrometry (GC-MS) system (Hewlett Packard 5890/5971)

- An ion chromatography (IC) systems (Dionex Aquion)

- A gas chromatography (GC) system (SRI 8610C)

- A NanoDrop™ OneC Microvolume UV-Vis Spectrophotometer (Thermo Scientific)

- A UV-Vis spectrophotometer (Agilent Technologies Cary 60)

The department has a large laboratory space for material and structural testing. There are three material testing frames and actuators, as well as equipment dedicated for concrete specimen testing. The capacities for material testing actuators are: 30 kN (quasi-static only) and 50 kN (two machines; dynamic/cyclic). The laboratory has a strong floor to enable full-scale testing of structures until failure. There are two actuators and a large testing frame. The capacities of two actuators are 500 kN and 250 kN, both controlled by hydraulic pressure with the ability to apply dynamic/cyclic loading.

The Center for Accessibility and Safety for an Aging Population (ASAP Center) is a multidisciplinary collaboration organized to conduct research in the primary area of transportation engineering, as well as performing educational and outreach programs. With motivation from Florida's large number of senior residents, the reported relatively high involvement of seniors in traffic crashes nationwide, and their special needs for transportation, the theme of the center is to provide safe and accessible transportation to the aging population. The center is supported by a strong research team from various disciplines including civil engineering, urban planning, geography, psychology, and health care management.

Center for Advanced Power Systems (CAPS) is a multidisciplinary research center organized to perform basic and applied research to advance the field of power systems technology with emphasis on application to electric utility, defense, and transportation. It has core competencies in the areas of power systems modeling, analysis, and control in the context of real-time digital simulators, power electronics, electrical machines and drive systems, superconductivity, and thermal systems analysis.

The vision of the Center for Intelligent, Systems, Control, and Robotics (CISCOR) is to use state-of-the-art technology to develop practical solutions to problems in systems, control, and robotics for applications in industry and government. CISCOR faculty come from Mechanical Engineering, Electrical and Computer Engineering, Computer Science, and Statistics and provide expertise such as mechanical design, dynamic modeling, control, artificial intelligence, pattern recognition, and computer vision.

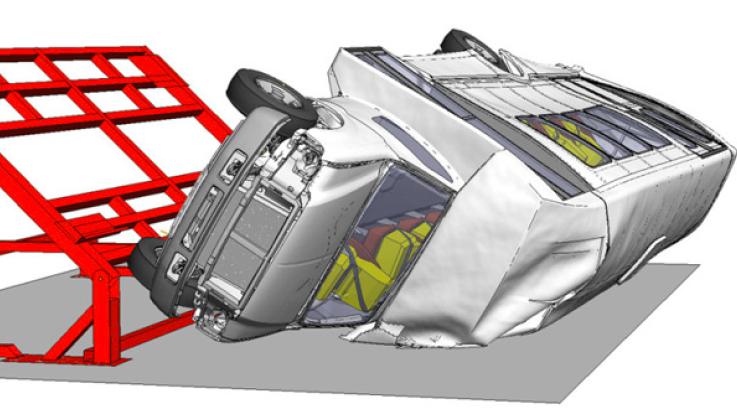

The Crashworthiness & Impact Analysis Laboratory - The State of Florida acquires about 300 cutaway buses every year. The Transit Office of the Florida Department of Transportation established the Crashworthiness Evaluation of Cutaway Buses Program in 1999. The Crashworthiness Evaluation Program has a mission of using cutting-edge computational mechanics and experimentation to ensure the safest paratransit services in the State of Florida. CIAL's research interests and expertise include applied computational mechanics and numerical analysis, non-linear, dynamic finite element methods, computer modeling, contact, impact and penetration problems, crashworthiness, safety, vulnerability and survivability, energetic materials, and detonation science.

Energy and Sustainability Center (ESC) addresses the most challenging energy issues related to the use of alternative energy through the development of innovative solutions for consumers and industry. Technologies of interest and areas of expertise include: off-grid zero emission buildings, algae photobioreactors, solar-thermal tri-generation systems, waste heat recovery, solar driven power cycles, fuel cells, and thermodynamic optimization of energy conversion systems.

Florida Center for Advanced Aero-Propulsion (FCAAP) is a State Center of Excellence involving FSU, the University of Florida, the University of Central Florida, and Embry-Riddle University. The principal focus of FCAAP is on aerospace and aviation research and technology, and FCAAP's efforts in this industry are having a major impact on Florida and the entire nation. FCAAP's state-of-the-art facilities include: 1) a polysonic wind tunnel, 2) a subsonic wind tunnel, 3) an anechoic wind tunnel, 4) a high temperature jet facility, and 5) a short take-off and vertical landing facility.

The FREEDM Systems Center (FREEDMSC) and Future Renewable Electric Energy Delivery and Management (FREEDM) initiative is the product of a collaborative effort between Florida A&M University, Florida State University, North Carolina State University, Missouri University of Science and Technology, and Arizona State University to establish secure, sustainable, and clean energy.

The multidisciplinary High-Performance Materials Institute (HPMI) performs research for emerging advanced composites, nanomaterials, multifunctional materials and devices, and advanced manufacturing. Currently, HPMI is involved in four primary technology areas: High-Performance Composite and Nanomaterials, Structural Health Monitoring, Multifunctional Nanomaterials Advanced Manufacturing and Process Modeling. Over the last several years, HPMI has proven a number of technology concepts that have the potential to narrow the gap between research and practical applications of nanotube-based materials.

The Florida A&M University – Florida State University College of Engineering maintains a Machine shop for support of research programs and of undergraduate and graduate education. The Machine Shop assists students, faculty, and staff with their cutting edge research and education by providing the necessary knowledge, equipment, and experience in machining and fabrication. In addition to offering the latest in CAD/CAM programs, the COE Machine Shop is equipped with a Haas CNC lathe, Haas CNC mills, and an Omax water jet machining center, enabling the shop to offer a high level of part accuracy for a variety of manufacturing processes.

For more information or to request services, visit the machine shop web page.

The mission of the National High Magnetic Field Laboratory (NHMFL), as set forth by NSF, is: "To provide the highest magnetic fields and necessary services for scientific research conducted by users from a wide range of disciplines, including physics, chemistry, materials science, engineering, biology and geology." In line with this, it generates the world's highest DC magnetic fields. ME researchers in the Maglab perform research and development projects involving very low temperature science and technology, relevant to the cooling of superconducting magnets.

The CREST CoMand focuses on the additive manufacturing of conventional and novel device structures. Specifically, the effort towards ab-initio fundamental understanding of material-property relationships that govern the working forces behind high-rate applications for bio, energy and production of light-weight structures.

The RIDER Center promotes all-embracing and equitable disaster resilience for vulnerable populations and probes the underlying causes of disaster vulnerability in communities. This is done while accounting for infrastructure characteristics and social needs. Their significance is assessed through various computational methods such as machine learning, causality, and regression models. These goals are critical since the associated risks are heterogeneous across population groups and space dependent on the available network, infrastructure, land use, and other localized conditions.

Transportation Engineering Laboratory aims to develop innovative and novel solutions to meeting mobility, accessibility and safety needs. Fully equipped with the state of the art equipment and software, the laboratory research areas include connected and automated vehicles, smart cities and urban mobility, freight logistics and traffic operations and safety.