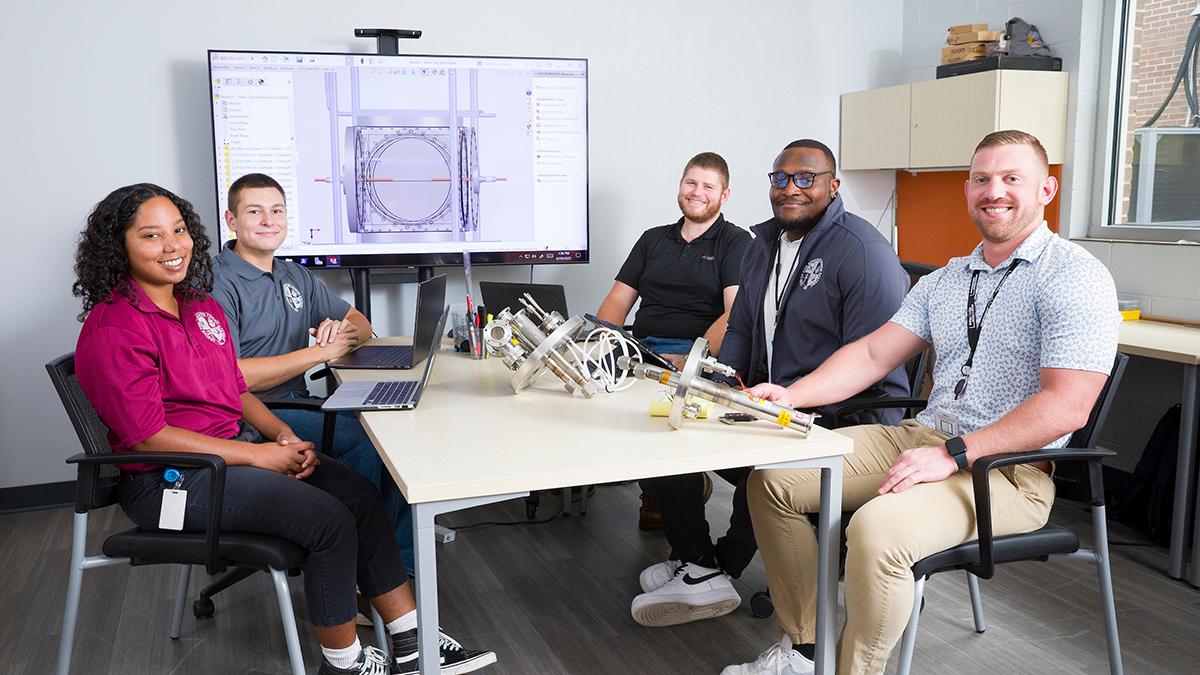

(Left-right): Raquel Marriott, William Touza, Peter Cheetham, Ph.D., Chris Akporoghene, and Lucas Grice work together on the design phase of the Integrated Zero-Emission Aviation (IZEA) project at the Center for Advanced Power Systems (CAPS) in Tallahassee, Florida. (Scott Holstein/FAMU-FSU College of Engineering)

Joint College of Engineering team develops breakthrough liquid hydrogen cooling technology to power next-generation sustainable aircraft

At the FAMU-FSU College of Engineering, imagination meets innovation as researchers embark on an exciting journey into the future of aviation.

Teaming up with NASA’s Integrated Zero-Emission Aviation (IZEA) project, they are pioneering an innovative initiative to create a safe and efficient liquid hydrogen cooling system for what could be the next generation of aircraft—a hydrogen electric aircraft powered by clean fuel that produces zero emissions and could redefine sustainable air travel.

Testing “Cool Technologies” for Future Flight

Peter Cheetham, an assistant professor of electrical and computer engineering at Florida State University and the joint FAMU-FSU College of Engineering, is leading the “testbed” phase of a five-year project that began in 2022. As a researcher at the Center for Advanced Power Systems, Cheetham is excited to contribute to this transformative work alongside fellow researchers in the IZEA project.

“This sort of work has been done before, but we believe this is the first time it’s being attempted in a university setting,” Cheetham explained, emphasizing the project’s pioneering nature. “What we’re working on involves the design and testing of helium/hydrogen heat exchange system. At the end we will conduct several thermal experiments aimed at maximizing the efficiency of cooling systems for electrical devices on the aircraft.”

This effort is supported by a $10 million grant from NASA’s University Leadership Initiative. To reach the testbed stage, a team of faculty researchers who are experts from multiple disciplines—including aerospace engineering, materials science, electrical engineering and environmental technology—forged a path toward development.

Superconductivity Meets Sustainable Aviation

“The IZEA project grew out of a collision of ideas in superconductivity, cryogenics, airframe design and simulation and hybrid-electric power systems,” according to Lance Cooley, a professor of mechanical and aerospace engineering and director of the Applied Superconductivity Center at the college. Cooley is overseeing the entirety of the IZEA project.

“Since liquid hydrogen fuel is both very cold—cold enough to allow superconductors to be used—and powerful enough to deliver performance better than jet fuel, NASA embraced our plan to validate new technology and obtain the first data for integrating the tremendous cryogenic cooling of liquid hydrogen with a hybrid-electric system,” Cooley explains. “Armed with the data, IZEA concepts could appear in the airline fleet within a couple of decades.”

The FAMU-FSU team collaborated with researchers from the University of Buffalo, the University of Kentucky, Georgia Tech, Illinois Institute of Technology, University of Tennessee, Raytheon, Boeing, and the Advanced Magnet Lab, Inc., and they worked on everything from the design of the aircraft and the motor to the hydrogen tanks needed for the mission.

Fueling the Future With Zero-Emission Aviation

Powering an electric aircraft with hydrogen focuses on enhancing efficiency, reducing noise pollution and achieving zero emissions. These aircraft use hydrogen fuel cells and hydrogen turboelectric generators to operate high-efficiency electric motors that drive the fans. However, challenges related to safety and efficiency must be addressed before this type of aircraft can become viable.

Along with Cheetham, faculty researchers Wei Guo, Chul Kim, Juan Ordonez and Sastry Pamidi are addressing the thermal challenges of the aircraft.

“We are focusing on the cooling requirements necessary for the aircraft’s operation,” Cheetham explained. “For instance, during takeoff, the power demand is twice as high as it is during cruising and adds additional strain on the thermal management system. We believe that liquefied gases, such as cryogens, can enhance efficiency in this regard.”

Engineering Challenges: Space, Weight and Efficiency

Another challenge they face involves the unique constraints of the aircraft environment, where space is limited and efficiency is paramount. The thermal system designed by the researchers must be lightweight, compact and powerful.

“On the ground, our devices can be any size, but in the air, we must optimize for space,” Cheetham noted.

During the testing phase, the team is developing a scalable system model to evaluate before finalizing the design for the actual aircraft. The team is creating, fabricating and testing a hydrogen/helium heat exchange system. They plan to thoroughly test the system to explore its limits, prioritizing both safety and efficiency.

From Design to Fabrication

Cheetham explains how they developed the design for this project. “At the Center for Advanced Power Systems, we have been designing helium gas-cooled devices for electric ships for many years, and there is a synergy between ships and aircraft,” Cheetham explains.

“We draw our ideas from multiple sources, borrowing and synthesizing them to create something new,” Cheetham continues. “It’s a process. We know who to consult, what materials we need and how to interface effectively. We understand who we can rely on to complete tasks safely.”

One reliable source mentioned by Cheetham is the FAMU-FSU College of Engineering Machine Shop. This facility enables researchers at the college to bring their designs to life. Managed by Jeremy Phillips, the shop assists students and researchers with various projects.

“The Machine Shop is essential for the exciting experiments we are conducting here,” Cheetham says. “We couldn’t embark on this project without the support of these skilled technicians who help fabricate our designs into functional prototypes.”

What’s Next for Hydrogen Electric Aircraft Research?

After fabrication, the next step is testing. “We plan to push the limits and evaluate the performance,” Cheetham says. “As the project progresses, we are optimistic about its potential impact on the aviation industry.”

Cheetham is eager to continue the research, emphasizing that the insights gained will be invaluable for advancing sustainable aviation practices.

“Regardless of the outcome, the knowledge we uncover will make a significant contribution to the field,” he explains. “Our initiative is not only focused on technological advancement; it also aims to nurture the next generation of engineers.”

Editor’s Note: This article was edited with a custom prompt for Claude Sonnet 4, an AI assistant created by Anthropic. The AI optimized the article for SEO discoverability, improved clarity, structure and readability while preserving the original reporting and factual content. All information and viewpoints remain those of the author and publication. This article was edited and fact-checked by college staff before being published. This disclosure is part of our commitment to transparency in our editorial process. Last edited: 10-03-2025.

RELATED ARTICLES

FAMU-FSU Researchers Pioneer New Hydrogen Storage System for Zero-Emission Aviation

New cable design research supports U.S. Navy quest for all-electric ship