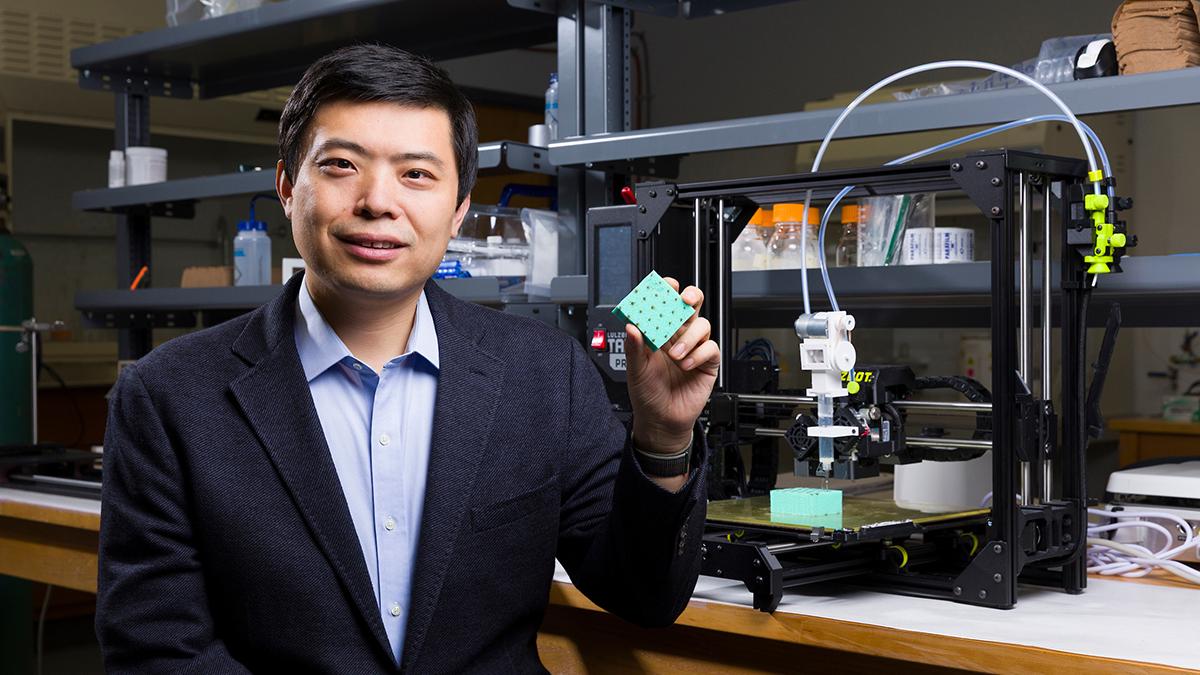

Jizhe Cai holds a strut-foam sample in a lab in the joint FAMU-FSU College of Engineering in Tallahassee, Florida. (Scott Holstein/FAMU-FSU College of Engineering)

New study combines foam technology with additive manufacturing to create stronger, lighter aerospace materials

A breakthrough in materials science could lead to safer helmets, stronger cars, and lighter aircraft through an innovative combination of foam technology and 3D printing. The new approach creates strut-foam Interpenetrating Phase Composites (IPCs)—advanced materials that are both lightweight and highly impact-resistant.

The research is led by FAMU-FSU College of Engineering Assistant Professor Jizhe Cai through a National Science Foundation (NSF) project.

Breakthrough Materials Combine Lightweight Design with Maximum Impact Protection

“We’re developing lightweight, impact-absorbing materials that can protect people and equipment in extreme environments,” Cai said. “These materials are crucial for personal protective gear, automotive safety systems, and aerospace structures, where both strength and low weight are essential.”

The approach combines the energy absorption properties of advanced foam composites with the design flexibility and performance tuning capabilities of 3D printed structures. This new type of material can be customized exactly how researchers want it, which helps it become stronger and better at absorbing energy. The result is impact resistant materials that are strong, light and highly customizable.

“These new composites could lead to safer helmets and armor, lighter aerospace panels, and more efficient energy-absorbing systems in vehicles,” Cai said. “They’re designed to protect people and make technology more sustainable at the same time.”

Revolutionary 3D Printing Method Works Inside Foam Structures

To create these new customizable materials, the researchers are developing an innovative in-foam printing (IFP) system—a new type of 3D printer that can print within polymeric foam. Instead of building a structure layer by layer on a flat surface, the researchers can inject liquid resin into the foam’s pores. The resin flows, spreads and hardens in place to form mechanical supporting struts within the foam, creating a hybrid structure from the inside out.

“We use computational and mechanics modeling to study how liquids move and solidify in porous materials,” Cai said.

The team takes detailed 3D scans of the foam’s internal structure, recreates it in computer models, and runs simulations to predict how strong the material will be and when it might break. They then test physical samples through compression and impact tests to validate their computational predictions and ensure the materials meet aerospace industry standards.

Multi-University Partnership Accelerates Aerospace Materials Research

FAMU-FSU College of Engineering researchers in the Department of Industrial & Manufacturing Engineering and Department of Mechanical & Aerospace Engineering are partnering with Texas A&M University (TAMU) in an interdisciplinary effort. This collaboration combines advanced manufacturing, materials science, structural characterization, simulation and experimental mechanics to develop these new hybrid materials.

“My team will work closely with Professor Mohammad Naraghi’s team at TAMU,” Cai said. “We are providing students with hands-on experience in the IFP process and giving them exposure to experimental mechanics and advanced aerospace materials research across institutions.”

From Safer Helmets to More Efficient Aircraft

This research, if successful, will improve lives and make everyday activities safer. These advanced aerospace composites could lead to safer helmets, stronger cars and more efficient airplanes. As we consider safety and environmental responsibility, it’s crucial to develop materials that are both lighter and more affordable.

This project goes beyond aerospace materials—it’s about creating opportunities for students and advancing engineering education. Through this project, Cai’s group aims to engage local students in hands-on demonstrations that connect mechanics, advanced manufacturing and materials science to real-world applications. The project also seeks to build a sustainable pipeline that inspires and equips students to pursue aerospace engineering degrees.

“This NSF project directly supports our new Aerospace Engineering graduate program in the MAE Department starting in 2025, the first of its kind at an HBCU,” Cai said. “It will train students to design and manufacture advanced aerospace materials through hands-on research in manufacturing, modeling and characterization, preparing them for impactful careers in aerospace and defense.”

The project entitled “Excellence in Research: Mechanics of Interpenetrating Strut-Foam Smart Composites for Aerospace and Beyond,” is funded by a $786,000 National Science Foundation grant through Florida A&M University.

Editor’s Note: This article was edited with a custom prompt for Claude Sonnet 4, an AI assistant created by Anthropic. The AI optimized the article for SEO discoverability, improved clarity, structure and readability while preserving the original reporting and factual content. All information and viewpoints remain those of the author and publication. This article was edited and fact-checked by college staff before being published. This disclosure is part of our commitment to transparency in our editorial process. Last edited: November 9, 2025.

RELATED ARTICLES

High-tech foam offers new tool for developing stem cells

Florida Center For Advanced Aero-Propulsion Advances Aerospace Industry “Top Gun” Style