(L-R) Arijit Ghorai, Ph.D., and Hoyong Chung, Ph.D., pose in the Interdisciplinary Research and Commercialization Building (IRCB) in Tallahassee, Florida on August 12, 2025. The research team used lignin and carbon dioxide to create a new kind of biodegradable polyurethane that doesn't contain toxic chemicals. (Scott Holstein/FAMU-FSU College of Engineering)

New synthesis method eliminates hazardous chemicals while creating high-performance sustainable polymers

Hoyong Chung’s laboratory at the FAMU-FSU College of Engineering has demonstrated a breakthrough method for producing polyurethane using lignin from plant cell walls and carbon dioxide, eliminating the need for toxic isocyanates in the manufacturing process.

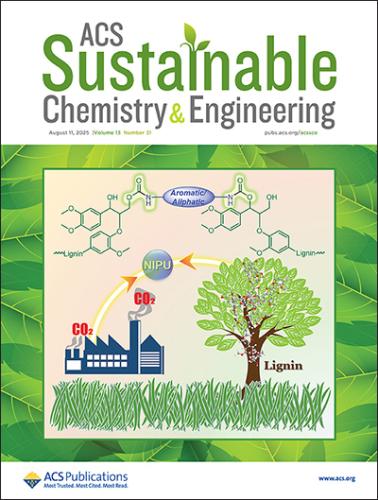

The research, published in ACS Sustainable Chemistry & Engineering, shows for the first time how lignin—a material found in plant cell walls—can be combined with captured carbon dioxide to create non-isocyanate polyurethane with properties matching or exceeding conventional materials.

Eliminating Toxic Manufacturing Chemicals

Traditional polyurethane production relies on isocyanates, compounds that are highly reactive and hazardous to human health. Chung’s method eliminates these toxic ingredients entirely while maintaining the polymer’s desirable heat regulation properties, processing flexibility and structural strength.

“We’ve created a high-quality polymer using fewer steps, less energy and no toxic ingredients,” Chung said. “It’s better for the environment, better for people and easier to manufacture.”

The process uses lignin’s naturally occurring hydroxyl groups to react with carbon dioxide, creating polyurethane networks without requiring hazardous chemicals. This addresses a significant safety concern in polymer manufacturing while maintaining material performance.

Improved Manufacturing Efficiency

The new synthesis method requires fewer reaction steps than conventional approaches while producing equivalent or superior material quality. This efficiency advantage addresses a key limitation that has prevented other biomass-based alternatives from achieving commercial viability.

“Scalability is big for us, because we are a polymer science group and we’re always trying to scale up and commercialize and industrialize our research technology,” Chung said. “This has much better processability compared to other alternatives used to recreate polyurethane. We use far fewer reaction steps to produce the same quality or higher quality of material.”

The resulting polyurethane maintains conventional versions’ strength and heat resistance while dissolving easily in solvents for manufacturing applications. This combination of properties has been difficult to achieve with other sustainable polymer alternatives.

Utilizing Industrial Waste Streams

Lignin represents an abundant but underutilized resource, typically treated as waste in pulp and paper processing operations. The research demonstrates how this industrial byproduct can be converted into high-value materials rather than being burned for energy recovery.

Chung’s laboratory has systematically explored lignin applications across multiple polymer types. Previous work published in 2024 showed lignin could be used to create polycarbonate materials. The current research extends these applications to polyurethane, which has broader industrial uses due to its flexibility and elasticity.

Chung first investigated lignin applications during graduate school, exploring its potential as an adhesive material. Despite limited research in the field at that time, he continued developing lignin-based technologies because of their potential for medical applications, energy systems, and sustainable materials.

Carbon Dioxide Integration

The method incorporates carbon dioxide directly into the polymer structure, converting a greenhouse gas into a functional material component. This approach aligns with carbon capture and utilization technologies that transform captured emissions into useful products rather than simply storing them underground.

By using waste lignin and captured carbon dioxide as raw materials, the process simultaneously addresses two environmental challenges: reducing industrial waste and finding productive uses for captured greenhouse gases.

Applications and Next Steps

Polyurethane materials are used in automotive components, construction materials, furniture, coatings and specialized industrial applications. The new synthesis method could provide a sustainable alternative for these uses while eliminating worker exposure to toxic isocyanates.

“Polyurethane is a very important material,” Chung said. “By producing it with a new and non-toxic method, we can help the world.”

The research team plans to continue developing the technology for commercial applications while exploring additional polymer types that could benefit from similar sustainable synthesis approaches.

Research Infrastructure and Support

The research was conducted in FSU’s Interdisciplinary Research and Commercialization Building, which provides access to advanced equipment and collaborative research opportunities. Chung credited the university’s research infrastructure for enabling the breakthrough.

“FSU gave me the space, the tools and the people to make this happen,” he said.

The work was supported by the U.S. Army Research Office and the Ministry of Trade, Industry & Energy of the Republic of Korea. Postdoctoral researcher Arijit Ghorai was the lead author of the study.

Editor’s Note: This article was edited with a custom prompt for Claude Sonnet 4, an AI assistant created by Anthropic. The AI optimized the article for SEO discoverability, improved clarity, structure and readability while preserving the original reporting and factual content. All information and viewpoints remain those of the author and publication. This article was edited and fact-checked by college staff before being published. This disclosure is part of our commitment to transparency in our editorial process. Last edited: 8/14/2025.

RELATED ARTICLES

Chung Named National Academy of Inventors Senior Member

Researchers Develop Biomass-Based Polymer that Can Absorb and Release Carbon Dioxide

FAMU and FSU Researchers Land $500K NSF Grant For Bio-Adhesive Study