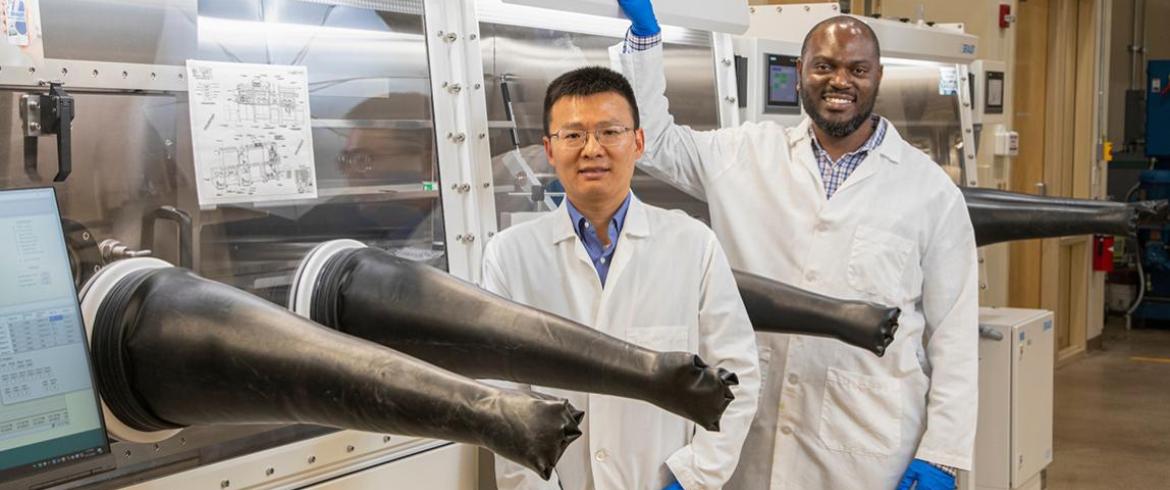

Zhibin Yu, Ph.D., left, and Tarik Dickens, both associate professors in industrial and manufacturing engineering at the FAMU-FSU College of Engineering received a half million dollars grant to research radiation detectors. (M Wallheiser/FAMU-FSU Engineering)

Researchers at the FAMU-FSU College of Engineering are leading a new study to develop perovskite-polymer composites that can be 3-D printed for high-resolution pixelated radiation detectors and other devices, like detector arrays.

Zhibin Yu and Tarik Dickens are associate professors in the joint college’s Department of Industrial and Manufacturing and researchers at the High-Performance Materials Institute. They hope to solve some of the challenges associated with processing and manufacturing these types of devices.

Organometal halide perovskites have garnered attention in the scientific community for their unique structural qualities. They have been identified as promising materials for photovoltaic and light-emitting devices. The team thinks they may hold the key to developing a new generation of low-cost composites used in optoelectronic manufacturing for radiation detectors.

“Radiation detectors that monitor and detect nuclear material use semiconductors made from inorganic single crystals,” Yu explained. “When the semiconductors are processed at high-temperature, they are difficult to scale. These new composites are scalable and have qualities that make them ideal for applications related to radiation detection.”

The researchers are synthesizing new semiconductor-polymer composites with better manufacturing flexibility than current materials. If successful, the composites can be processed into commodity plastics by solution casting, hot pressing, melt extrusion, and injection molding—techniques that allow manufacturers to produce radiation detectors of various shapes and sizes.

Among other reasons, Dickens says this research is important because, “It uses the fundamental processing knowledge we developed in the NSF CREST Center, which helped to build the first high-precision Additive Manufacturing Center on campus,” Dickens said. “These programs can be very collaborative in helping researchers and students find common ground to explore some cool science.”

Why Does It Matter?

There are several ways this research can enhance current nuclear material uses. For instance, to transport nuclear materials like highly enriched uranium and plutonium-239 on a vessel such as a ship, carriers must have large and accurate radiation detectors to safeguard the humans working around the materials. Large-area, low-cost radiation detectors enhance operation efficiency and improve quality control in many industrial mining and metallurgical processes. High-resolution pixelated radiation detector arrays also support nuclear medical diagnostics and boost the study of particle physics in outer space.

The study also has important educational benefits for students at the joint college. The grant creates a new educational program at Florida Agricultural and Mechanical University, a historically Black public university. The study targets the training of underresourced engineering students and fuels a workforce pipeline in manufacturing, electronics, semiconductors and national security industries.

The project includes an educational element that supports students. The grant will create a new educational program at Florida Agricultural & Mechanical University (FAMU), a public Historically Black College/University. The study targets the training of underresourced engineering students and fuels a workforce pipeline for the manufacturing, electronics, semiconductors, and national security industries.

Where’s the Money Coming From?

The National Science Foundation (NSF) Excellence in Research, Division of Electrical, Communications and Cyber Systems from Equivalence for Excellence in STEM funds the $499,776 study through FAMU. The Equivalence for Excellence in STEM (EES, formerly known as HRD) program, is the same division that sponsors the CREST award.

RELATED ARTICLES

Engineering Researchers Win Commercialization Funding from FSU

Research at the Extreme Helps Students Forge Their Path for a Career in 2030 and Beyond