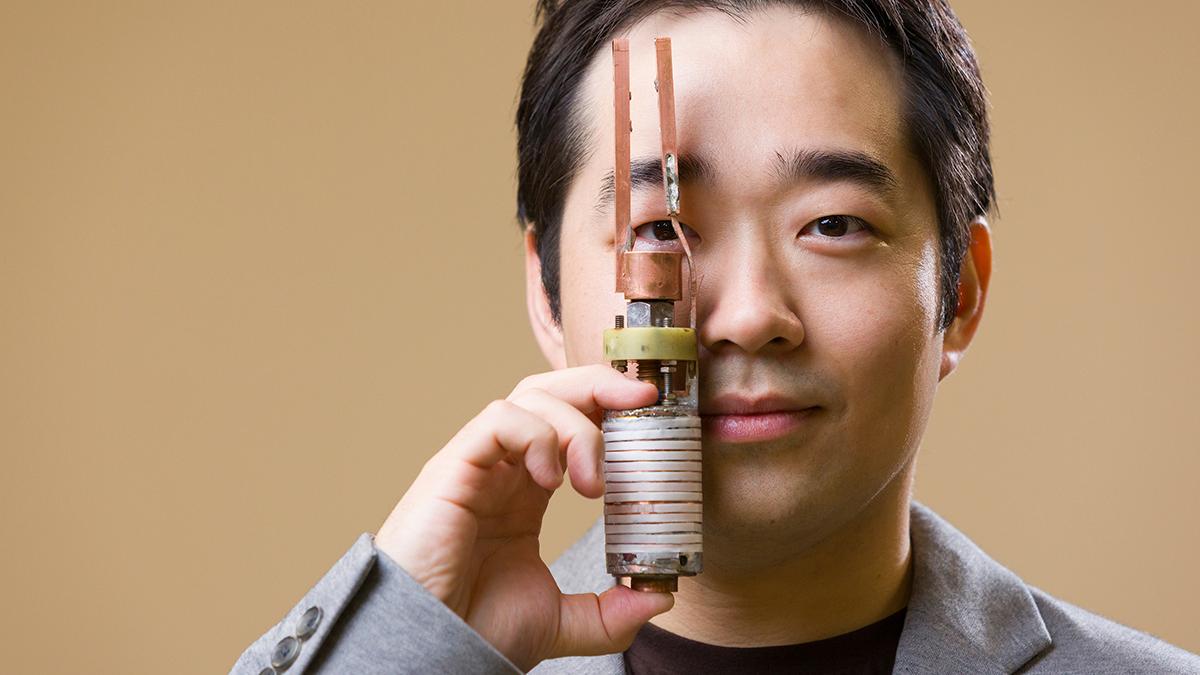

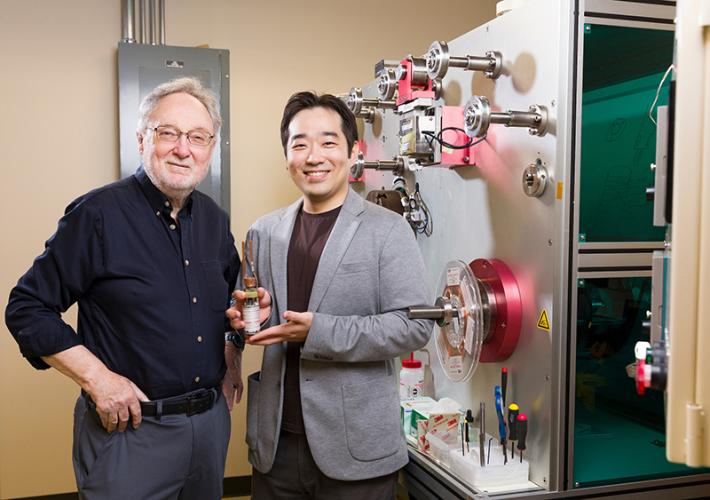

Researcher Jeseok Bang, Ph.D., poses with Little Big Coil Number 9 (LBC9) in the Applied Superconductivity Center (ASC) in Tallahassee, Florida on October 13, 2025. The LBC9 test coil created a new record of 48.7 tesla. (Scott Holstein/FAMU-FSU College of Engineering)

A miniature superconducting magnet developed by FAMU-FSU College of Engineering professors has shattered the previous world record for magnetic field strength, reaching an unprecedented 48.7 tesla at the National High Magnetic Field Laboratory—more than 3 tesla beyond the previous benchmark.

Professors David Larbalestier and Seungyong Hahn pioneered the breakthrough technology behind “Little Big Coil,” a salt-shaker-sized electromagnet that achieved what many thought impossible. Their innovation in no-insulation winding techniques enabled this tiny device to generate magnetic fields nearly 50 times stronger than industrial magnets used to lift cars in junkyards.

Revolutionary No-Insulation Technology Powers Record-Breaking Field

The experimental magnet, designated LBC9 (Little Big Coil No. 9), generated 17.6 tesla inside MagLab’s 31 tesla NHMFL Bitter magnet, producing a combined field of 48.7 tesla and surpassing the previous 45.5 tesla record set in 2017. Tesla measures magnetic field strength—the fundamental unit for quantifying these powerful forces.

The breakthrough stems from Professor Hahn’s invention of no-insulation winding technology, which allows the coil to carry significantly higher electrical current by eliminating traditional insulation materials. This approach has gained widespread adoption among groups developing REBCO magnets, including two leading manufacturers of tokamak fusion power plants.

“Obviously, this is another important milestone in the history of high-field REBCO magnet technology, an outcome after close collaboration among international teams over a decade,” said Hahn, now at Seoul National University. “We have newly identified so many unknowns and together overcome the consequent challenges to come this far.”

“This was not just a little world record, to beat the previous mark of 45.5 T by more than three tesla, it’s amazing,” said Larbalestier, who also serves as MagLab Chief Materials Scientist. “This coil is little in size, but it’s big in field and big in stress.”

Proof of Concept for Next-Generation Applications

Wound with REBCO (REBa2Cu3O7-δ) superconductor material capable of conducting electricity without resistance, this prototype demonstrates the potential for smaller, more powerful electromagnets across multiple industries. Potential applications include electric aircraft motors, fusion energy reactors, and advanced medical imaging systems.

While designed as a test coil, the achievement proves that superconducting magnets can exceed the field strength of MagLab’s flagship 45 tesla hybrid magnet, which held the Guinness World Record for highest continuous magnetic field for more than 20 years.

The milestone emerged from a collaborative project at MagLab’s Applied Superconductivity Center, supported by the Department of Energy Office of Fusion Energy Sciences. The National High Magnetic Field Laboratory, funded by the U.S. National Science Foundation, is headquartered at Florida State University.

“This is what we do,” said MagLab Director Kathleen Amm. “We push the boundaries to build the strongest magnets in the world for research, and to advance technology that transforms our world. I’m so proud of our team.”

“When the NSF and DOE join forces at NSF MagLab, we don’t just chase records—we break them,” said NSF Materials Research Division Director Germano Iannachione. “This high-field DC magnet pushes the boundaries of superconducting science and pulls new possibilities into reach for national security, energy, and beyond.”

Precision Engineering and Manufacturing Excellence

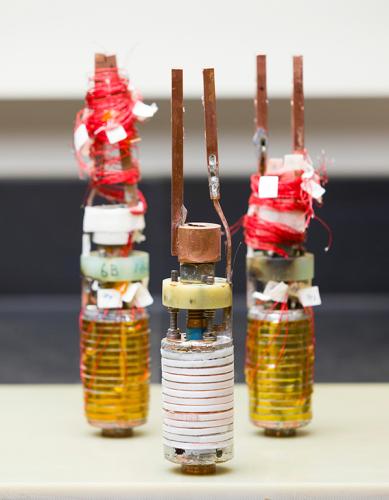

Despite measuring just 1.5 inches in diameter and 2 inches tall—small enough to hold in one hand—LBC9 contains more than 720 feet of superconducting REBCO tape precision-manufactured by Japan’s Faraday Factory.

“This is an outstanding accomplishment,” said Sergey Lee, CEO of Faraday Factory Japan. “We are proud to have contributed our superconductor material and expertise for it.”

Electromagnets face significant challenges in terms of mechanical and thermal stress. As magnetic fields intensify, stress increases quadratically, creating a risk of overheating and structural failure. The new coil benefited from collaboration on tooling and mechanical design with MagLab’s Magnet Science and Technology Division, building on lessons learned from the 2017 record attempt.

“MS&T is proud to have collaborated on establishing the Little Big Coil test platform from which we expect many more successes going forward,” said Tom Painter, director of the MS&T team.

Testing Multiple Coils Advances Research Capabilities

In a significant technical achievement, the team tested three coils simultaneously during the August magnet time experiment—LBC7, LBC8 and LBC9—using the 31 tesla NHMFL Bitter magnet. This marked a breakthrough in testing methodology, as technical limitations had previously restricted researchers to testing only one coil at a time.

Graduate student Jonathan Lee played a key role in addressing the technical issues that enabled multiple-coil testing, opening new possibilities for comparative research. Of the three coils tested, two broke records, with LBC9 achieving the highest field strength.

The coils were wound with REBCO tape from different manufacturers, allowing researchers to investigate how specific characteristics of tapes from various producers correlate with coil performance at extreme magnetic fields. This comparative approach helps identify the optimal materials and manufacturing methods for pushing toward even higher field strengths.

Meticulous Construction Reduces Energy Loss

ASC research faculty scientist Jeseok Bang wound the superconductor in tight loops more than 2,700 times, focusing intensely on smoothing the copper joints that connect each strand. The coil also features current leads made from OFHC copper (oxide-free high-conductivity copper), critical components that researchers plan to upgrade with superconducting materials to improve heat dissipation and performance further.

Bang’s meticulous two-month construction process proved critical to the magnet’s success by dramatically reducing resistive heating at non-superconducting joints—a major source of energy dissipation that limits performance and causes damage.

“That is the key difference between the previous one and this new coil. I was able to reduce the resistance by a factor of five,” Bang explained.

The achievement represents years of design work, computer modeling, testing and construction innovation to optimize performance.

“It’s all these little things that you have to do and he has really, really been persistent,” Larbalestier added. “What’s remarkable is that this is a testbed which is quite inexpensive, by which we can really take the best conductors anybody in the world can make, and then we really test them to their limits.”

Enabling Future Technologies

The record represents the latest advance in superconducting materials research with far-reaching applications. The Applied Superconductivity Center is currently helping to build new and improved electromagnets for CERN’s Large Hadron Collider particle accelerator, while collaborating with fusion energy companies to develop powerful superconducting magnets for experimental reactors.

“This is a technology that people want to use for fusion. They want to use it for electric motors for aircraft,” Larbalestier explained. “They want to use it for all sorts of things. So, a demonstration that you really can do something unique and world-record-breaking successfully, though not easy, has great potential to galvanize attention for many applications.”

The primary challenge remains manufacturing high-quality, high-performance superconducting wire without defects that can withstand extreme forces generated by high magnetic fields. The Little Big Coil testbed enables researchers to evaluate REBCO tape from manufacturers worldwide, testing materials to their limits to understand performance characteristics and identify paths toward higher field strengths.

“If we can generate higher fields,” Bang said, “All of the electromagnetic applications are promising.”

He has already set his sights on the next milestone, targeting the significant 50 tesla threshold.

“There are many, many things left and many details still to understand,” he said. “This is just another step. We are still fighting for 50 tesla.”

Little Big Coil is a collaborative project primarily supported by DOE Office of Fusion Energy Sciences Grant DE-SC0022011. The National High Magnetic Field Laboratory receives support from U.S. National Science Foundation Cooperative Agreement No. DMR-2128556 and the State of Florida. The project involves collaboration with Professor Seungyong Hahn’s group at Seoul National University in Korea and Professor So Noguchi’s group at Hokkaido University in Japan.

Editor’s Note: This article was repurposed from content originally published by the National High Magnetic Field Laboratory. This version was edited with a custom prompt for Claude Sonnet 4, an AI assistant created by Anthropic. The AI optimized the article for SEO discoverability, improved clarity, structure and readability while preserving the original reporting and factual content. All information and viewpoints remain those of the author and publication. This article was edited and fact-checked by college staff before being published. This disclosure is part of our commitment to transparency in our editorial process. Last edited: 10-22-2025.

RELATED ARTICLES

Seminar: Key challenges towards the dream direct current magnetic field of 50 T

Engineers at National MagLab create world-record magnetic field with small, compact coil

Superconductivity expert elected Fellow of Royal Academy of Engineering