Three teams led by Florida State University faculty members--including two at the FAMU-FSU College of Engineering--have received funding from the university to propel their pioneering research from the lab to the marketplace.

The researchers have been awarded a combined pot of $110,000 following their successful pitches at the university’s biannual GAP competition, an event organized by the Office of the Vice President for Research where faculty members present their ideas to a committee of businesspeople.

“The work produced by FSU faculty members pushes the boundaries in innovation,” said Vice President for Research Gary K. Ostrander. “These innovations can also be transformed into products and businesses that help people or solve technological problems. The GAP program provides instrumental support and mentorship to our researchers to help them move their ideas through the development phase and ultimately into the marketplace.”

Over the past 10 years, the GAP program has awarded university researchers more than $2 million for projects designed to develop new cancer treatments, wearable phototherapeutic products and advanced educational assessment tools.

The competition’s winning proposals are:

- A nanocarbon foam for thermal management of electronic devices: FAMU-FSU College of Engineering Professor Mei Zhang has developed a nanocarbon foam material that could be used in electronics to keep them from overheating. Currently, many technologies use what’s called a flat heat pipe made out of copper or aluminum. Zhang said her team could use the foam material to design a much more efficient pipe for electronics as they become smaller and even more flexible. She will use her GAP funding to further improve and develop the foam design to reach its optimal potential.

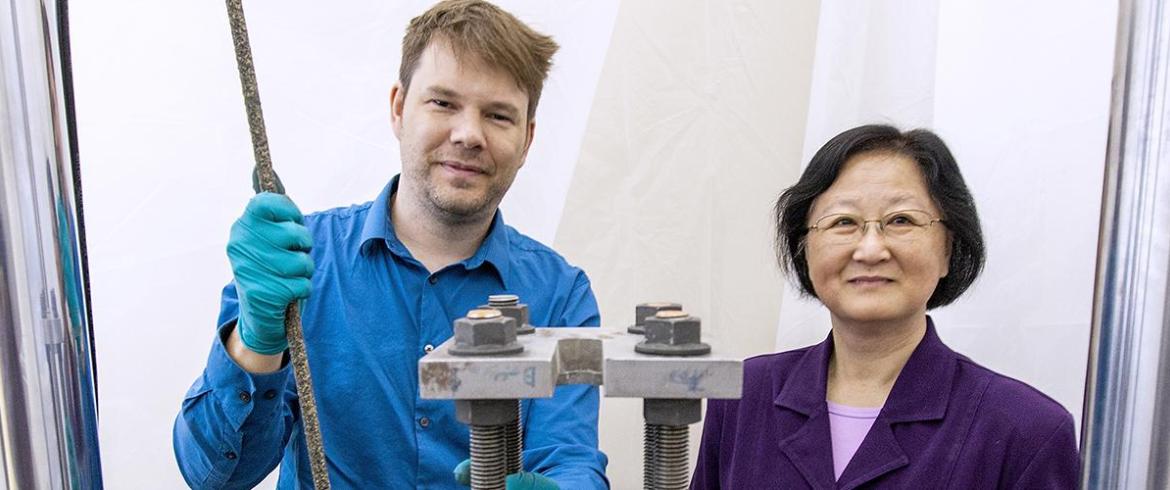

- A grip to test fiber reinforced rebar for concrete: Assistant Professor of Civil Engineering Raphael Kampmann has developed a novel tensile test grip that can test new material used to reinforce concrete. Concrete is widely used for construction projects because it is long lasting. However, it is also brittle and is reinforced with steel rods called rebar. New types of rebars are made with fiber reinforced polymers that are stronger and lighter than steel and not susceptible to corrosion. However, these new materials must be tested for strength so that regulatory agencies can guarantee the safety of new structures. The new test device allows for fast, reliable testing of these materials. Kampmann will use the GAP funding to validate the testing process.

- An innovative approach to teach resiliency: Karen Oehme, director of the Institute for Family Violence Studies, developed an online evidence-based toolkit to encourage wellness by helping students learn to manage stress in healthy ways and increase their sense of belonging. The project launched during summer 2018 and addressed issues such as trauma, stress management and anxiety and pointed students to resources that could help them develop skills needed to cope with serious mental health issues. Universities across the nation immediately expressed interest in the project to see if it could be adapted for their own use. Oehme and her team will use the GAP funding to develop ready-to-use templates for other universities so that each user institution could customize them with photos or videos reflecting their own university culture.