Rajan Kumar, Ph.D., is working on a Small Business Innovation Research (SBIR) Phase III study for the U.S. Air Force based on the military’s interest in measuring aero-optical distortions inherent in laser research and “finding a flow control solution to minimize these distortions for better performance of the laser system.”

As the federal space shuttle program was winding down, Florida movers and shakers sought a way to continue to develop cutting-edge technology in aerospace and aviation. Florida aimed to maintain its leadership role in space exploration—that it held for decades through NASA Kennedy, while also training the next generation of scientists and engineers at the state’s leading universities.

In 2008, a team led by the researchers at the FAMU-FSU College of Engineering responded to the call by the Florida Legislature to establish Centers of Excellence. Their proposal was ranked second out of 40-plus submissions and provided seed money to establish a multiinstitution Center of Excellence led by and headquartered at the FAMUFSU College of Engineering. Faculty, scientists and students at this Center collaborate with colleagues based at the University of Florida, the University of Central Florida and Embry-Riddle Aeronautical University.

And in its 10-year history, it’s mission accomplished—and mission still continuing—at the Florida Center for Advanced Aero-Propulsion (FCAAP).

“FCAAP is becoming nationally and internationally known as an excellent place for research,” said Lou Cattafesta, Ph.D., director of the center and an Eminent Scholar and professor at the FAMU-FSU College of Engineering.

The initial $11 million investment from the state offered the opportunity to build a 60,000-square-foot facility— the Aero-propulsion, Mechatronics and Energy Center—from the ground up, “which doesn’t usually happen in an academic setting,” he said. The facility houses FCAAP, 14 faculty and nearly 50 graduate students from multiple disciplines who work in state-of-the art testing facilities and labs. You will be hard pressed to find another facility of its caliber in its areas of focus—at any university.

Just in the past year, FCAAP has received 32 new grants and has more than $7.8 million in annual research awards. The center has 28 collaborations with other institutions and 27 with private industry.

One point of pride is the more than $6 million Polysonic Wind Tunnel, which can be used for tests with speeds ranging from Mach 0.2 (around 150 mph, the speed of a high-performance car) to Mach 5—five times the speed of sound!

“Thanks to our unique talent and facilities, we have assembled a leading national effort to advance high-speed transport research.”

— FARRUKH ALVI, PH.D.

Other research tools found at the Center include an Anechoic High Temperature Jet Facility (which can generate supersonic jets at temperatures over 2000°F), Subsonic and Supersonic Wind Tunnels, a STOVL (Short Take- Off Vertical Landing) Jet Facility and a Computational Physics Laboratory. The facilities are used by researchers and graduate students, as well as visiting scientists from government agencies, aerospace companies and collaborators from around the nation and the world.

“What we have is people with unique expertise coupled with equally unique facilities,” said Farrukh Alvi, Ph.D., an Eminent Scholar and professor who was director of FCAAP from its genesis until Cattafesta took the helm in 2017. “Thanks to our unique talent and facilities, we have assembled a leading national effort to advance highspeed transport research.”

Cattafesta’s research focuses on examining the possibility of a return to commercial supersonic flight. Introduced in 1976, the Concorde flew passengers at Mach 2, but the price— an average of $12,000 round-trip for 100 passengers—the massive amount of fuel it used, and the limitations imposed because of sonic boom ended the era in 2003.

“The technology is there to build a much more economical and quieter airplane,” he said. “A supersonic civil transport would be really cool. Fly to London in a couple of hours—and hopefully at a price that’s pretty much what you pay for coach now.” The plan, “is to make this viable—you’re talking about a 300-passenger airplane—that we all can afford to go on.”

Resident researchers cover a multitude of disciplines. While others are reaching for the sky, Professor Neda Yaghoobian’s research pretty much keeps her feet on the ground.

“In general, my work studies the thermal-fluid dynamic interactions at the interface of the Earth and the lower atmosphere,” said Yaghoobian, who recently joined the faculty as an assistant professor. The “fluid” she usually works with is air—our atmosphere. “The problems that could be studied are pollution dispersion in urban areas, air quality, human health and comfort, energy use and energy harvesting.”

A recent analysis discussed how the air flow over the trees and terrain affected the trajectory of a golf ball, but her work and that of her colleague Kourosh Shoele, Ph.D., has other important real-world applications.

For example, with information about the strength and direction of a hurricane’s winds and the locations of natural and structural features, the duo could predict where damage is likely to occur and thereby help communities better plan and respond to extreme weather events.

Shoele, another recent addition to the faculty, uses computational techniques to study, among other things, how air interacts with the structure of aircraft wings with a goal of making them lighter and more flexible. While his computer is key, the assistant professor also spends time observing animals, including birds, insects and fish.

“The interesting thing about natural species is that each one uses a particular kind of motion and each one uses its own ‘best’ way to fly,” he explained. “They learn through years and years of evolution how to do things the perfect way.”

The goal, he said, is not to create an airplane that recreates the flight of an eagle.

“We need to learn from those biological systems, to see what we need to take and what parts we can ignore in our engineering design,” said Shoele. “In many cases people try to mimic what they see in biology, but as an engineer you never mimic, you just learn from them and use those principles to design the system according to your needs. That’s what I’m looking for.”

“A supersonic civil transport would be really cool. Fly to London in a couple hours—and hopefully at a price that’s pretty much what you pay for coach now.” The plan, “is to make this viable—you’re talking about a 300-passenger airplane—that we all can afford.”

— LOU CATTAFESTA, PH.D.

Nature can inspire revolutionary improvements. In industry, innovation can be stifled by manufacturers limiting to incremental improvements on what already exists.

“Sometimes during this process, you end up with a product that is doing the job, but it doesn’t do it efficiently. It doesn’t do it with minimal fuel use or just does what people want to see,” Schoele said. “I think part of my job is to break this obstacle.”

And if there’s resistance to change? “That’s the whole point of being in academia. You need to do something that excites people. Show them a better alternative from what they always practice.”

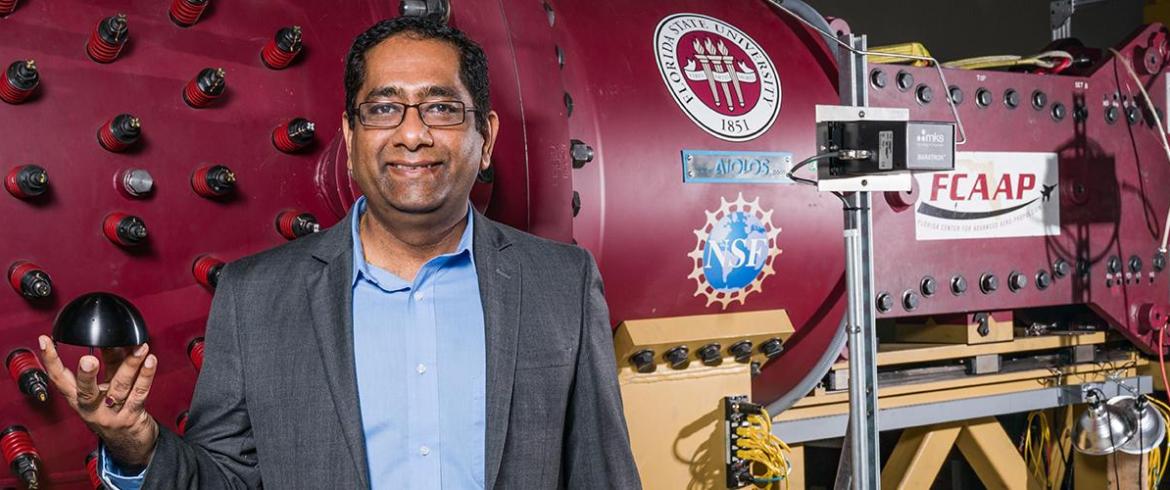

Associate professor Rajan Kumar, Ph.D., focuses on subjects that fly much faster and higher than today’s jets.

“Right now in the nation, whether it’s Air Force, Army or Navy, they all have hypersonic programs—anything which goes above Mach 4-5,” he said. “It is happening and that’s where the next 10 or 15 years of research will be. We are ready for that. We have the Polysonic Wind Tunnel that can reach those speeds, (and) we are building the necessary tools to explore aerodynamics in this flight regime. As an example, we are collaborating with the Air Force, enabling their next-generation hypersonic air vehicles.

“Because we have these unique tools and facilities, a number of major aerospace companies like Lockheed Martin, Boeing and Northrop Grumman come to us for their testing needs on a regular basis and we are working with a number of other commercial companies to build the next generation airplanes,” he continued.

While innovation gets attention, educating the next generation of aeroscientists is always on the minds of our faculty. “All those graduate students that work in our facilities, they get trained in the most advanced test and diagnostics,” said Kumar. “They find jobs very quickly because they are trained in the right areas with the right skills.”