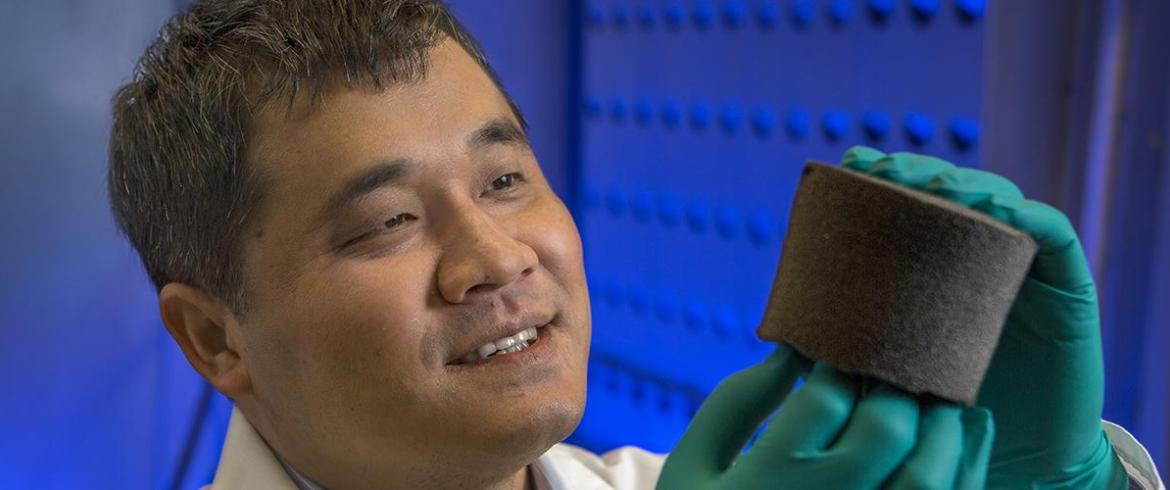

Changchun "Chad" Zeng, an associate professor of engineering at the FAMU-FSU College of Engineering, developed an advanced foam technology that has gone on to benefit several elite athletes at FSU.

Originally published by Florida State University News on Feb. 7, 2019

When a technology developed by university researchers is licensed and integrated into a commercial product, that’s considered a resounding success. But when that same product eventually benefits student-athletes at the researchers’ own university, that’s cause for special celebration.

This was exactly the case for an advanced foam technology developed by FAMU-FSU Engineering faculty at Florida State University’s High Performance Materials Institute. The foam, which was originally designed for use in prosthetics, now provides critically supportive padding in the TayCo Ankle Brace, a sophisticated bracing system used by athletes at Florida State.

Along with several FSU football players, star softball player Jessie Warren was one of many notable athletes to benefit from the brace, which was designed by an athletic trainer at the University of Notre Dame. Last summer, Warren could be seen wearing the brace during her team’s historic run to the national championship.

“You always feel a sense of satisfaction when your research leads to products that benefit people,” said FAMU-FSU College of Engineering Associate Professor Changchun “Chad” Zeng, who led the team that developed the foam. “But in this case, the people benefiting are elite athletes at your own university. This is really an extremely gratifying feeling that just cannot be described by words.”

Zeng’s foam was the product of a two-year project funded by the U.S. Department of Veterans Affairs. Since being exclusively licensed to the LLC Auxadyne, the technology has experienced significant commercial success in athletic protective equipment and footwear.

Auxadyne President Joe Condon, whose company produces foam pads derived from Zeng’s cutting-edge material, said the TayCo brace is a uniquely fortuitous case of technology commercialization.

“Auxadyne’s foam pads are an excellent full-circle example of the great benefits of FSU’s research and commercialization efforts,” Condon said. “Auxadyne is now successfully commercializing this FSU technology through its manufacturing of the pads, and FSU’s athletes are benefiting, making the world a better place literally one step at a time.”

The foam’s mind-bending behavior affords it a number of distinct advantages over similar technologies, according to Zeng.

Most materials, when stretched in one direction, will shrink in other directions. Think of the way a sock or a dish towel seems to shrink in the middle when tugged on both ends.

“Our foams behave totally the opposite way,” Zeng said. “They expand in all directions when being stretched, and shrink in all directions when compressed. The structure that leads to this counterintuitive behavior also gives rise to other remarkable properties such as increased protective capabilities and superior comfort.”

Zeng said these impressive properties become especially valuable in a product like an ankle brace. Superior and unrestrictive fit, robust and resilient protection, effective energy dissipation and a light-weight composition make Zeng’s foam the perfect complement to an ankle brace’s rigid plastic skeleton.

For Jake Pfeil, FSU’s executive associate director of sports medicine and head athletic trainer for football, that auspicious combination of factors was too good to pass up. In fact, he and his staff incorporated the brace into their training and prevention regimens long before learning about its FSU connections.

“It’s unlike any other option that we have used in the past,” Pfeil said. “Unlike other ankle braces, the TayCo fits on the outside of the player’s cleat rather than inside of the cleat. The main benefit of this is comfort for the player. It is very difficult to find an ankle support that fits inside of a cleat that doesn’t cause the cleat to then feel too tight, but the TayCo brace can be easily and quickly put on without affecting the fit of the shoe.”

Along with the convenient and comfortable external fit, the TayCo brace allows for increased customization, so that bespoke braces can perfectly support the specific contours of an athlete’s cleated lower leg.

The brace can also serve as a walking boot substitute. When injured athletes wear walking boots, the thick stabilizing soles often lead to uneven foot strike with the ground — an unwelcome disruption of the athlete’s natural biomechanics. The brace, on the other hand, allows injured athletes to wear their own shoes while also benefiting from the brace’s reinforced support.

The brace’s foam lining helps avert stress-induced damage at important, high-impact areas of the leg. The foam also prevents the brace’s stays from migrating out of their appropriate positions, which could lead to “breakdowns in proper fit, discomfort and, most importantly, failure of the brace to support the ankle,” Pfeil said.

The high performance of the foam matched with the comfort and flexibility of the brace’s design has given Pfeil and his staff the confidence to introduce the TayCo brace into their everyday athletic training schemes.

As far as Pfeil is concerned, the world-class quality of the brace itself is enough to make it a mainstay in his training rooms. But the brace’s direct connection to the groundbreaking research conducted at FSU has become a point of pride.

“The TayCo brace proved itself to me and our players on the field, and I believe that, with further development, the brace will become more and more popular in many sports,” Pfeil said. “I am proud to know that such an innovative new product has such great characteristics and performance thanks in part to research and ingenuity at our outstanding university.”