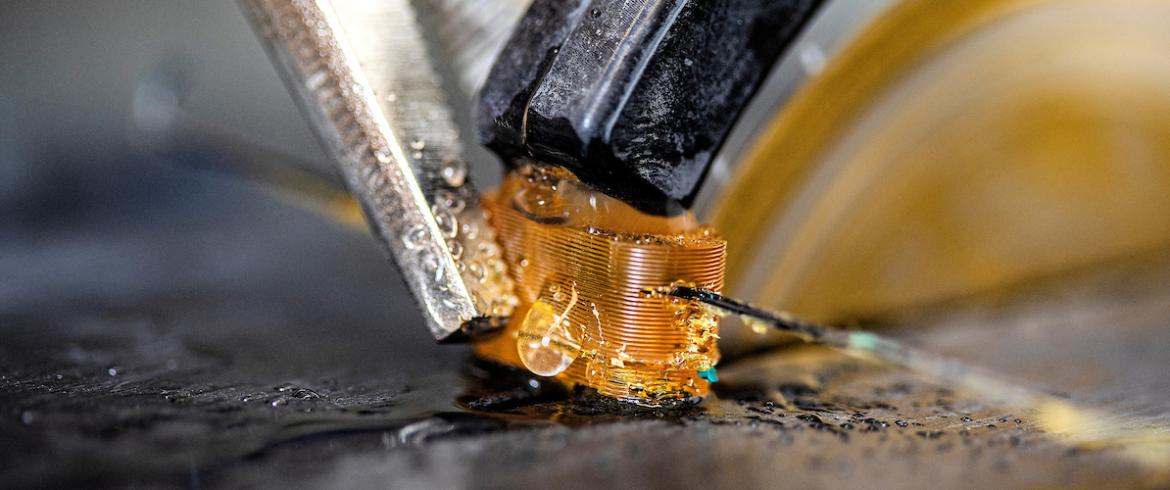

Engineering researcher Rebekah Sweat, Ph.D. and her team received commercialization funding from Florida State University for their work with epoxies and resins. Sweat’s group takes a mix of special fibers and casts them into a mold, which allows them to test the composites for their bonding capability and strength. Samples look like lollipops and are about the size of a fingertip. (M Wallheiser/FAMU-FSU Engineering)

With new FSU GAP award funding, industrial and manufacturing engineers make big strides in advanced materials testing invention

A team of FAMU-FSU College of Engineering researchers has developed an advanced materials testing device, a finding that may revolutionize how companies test polymer composites in the future.

Companies like 3M and Solvay develop and test polymer composites in search of lighter, more robust materials for the aerospace and automotive industry, but testing can be time-consuming and costly. Better testing methods have long been sought after in the industry.

Rebekah Sweat, an assistant professor in industrial and manufacturing engineering, worked with graduate and undergraduate students from the High-Performance Materials Institute on an invention to test advanced materials. The new device is a mold and testing fixture that will reduce costs and help speed up materials production.

“Companies specializing in advanced materials want to improve the bonding and resilience of their product to improve performance,” Sweat said. “Our device streamlines this process to rapidly test materials needed for manufacturing.”

The team’s device got the attention of the Florida State University GAP Commercialization Investment Program in 2020, when Sweat initially received a grant. Now, the invention has come to fruition and is nearly ready for market.

Doctoral candidate in industrial and manufacturing engineering, Ana De Leon, is the lead student researcher on the project. De Leon has optimized the mold designs into something ready for commercialization.

“I am impressed with how the molds facilitate the manufacturing process,” De Leon said. “I have been working with Dr. Sweat and Mehul Tank, a fellow graduate student. Our goal is to find a manufacturing partner to sell and license our molds. A patent is currently pending.”

The innovative device builds on a fiber bundle pullout test. Working with epoxies and resins, Sweat’s group takes a mix of special fibers, like carbon fiber and carbon nanotube yarns, and casts them into a mold. Then they test the composites for their bonding capability and strength. Samples look like lollipops and are about the size of a fingertip.

“Our molds work like baking when you pour batter into a shaped mold and place it in an oven,” Sweat explains. “You place your fibers in the mold, pour the resin on top and cure them in an oven to harden the polymer. From there, it is simple to cut and test the samples.”

Traditional fiber bundle pullout tests are manufactured by taking a fiber bundle and vertically incorporating and curing the fibers into the resin. Only a few samples can be made at a time, providing few and inconsistent results. With this new mold, researchers can create hundreds of samples and test them in a short amount of time. The data from the test is far more accurate and demonstrates which fibers pair best with resins.

“Our method uses less material and provides far better data than the traditional pullout test,” Sweat said. “To certify a material used in a product, you must confirm all the different properties and performance. Once finished, this performance data is used by design engineers for their end application.”

The novel testing procedure can be performed and replicated quickly, potentially being a game- changer in the industry. Sweat’s group plans to market the device as a set of molds with matched test fixtures to academia, government or industry. The device fits a mechanical frame that most laboratories would already have, and the fixture that fits in the frame is directly geometry matched to the samples from the mold for uniformity. The group plans to license the design to a manufacturing partner.

“I am very excited about the future of this technology,” Sweat said. “Novel materials can be implemented quicker because of tests like we are developing. New materials can be ramped up faster. There will be less hesitancy to push the boundaries of new materials because it will be less costly and time-consuming.”

The journal Composites Science and Technology (Elsevier) recently published their work.

The High-Performance Materials Institute is a multidisciplinary research facility at FSU that is closely aligned with the FAMU-FSU College of Engineering. It is a leading center of excellence for research and education for advanced materials. The HPMI center works with aerospace, automotive, energy, 3-D printing, electronics, sports technology and biomedical areas of interest.