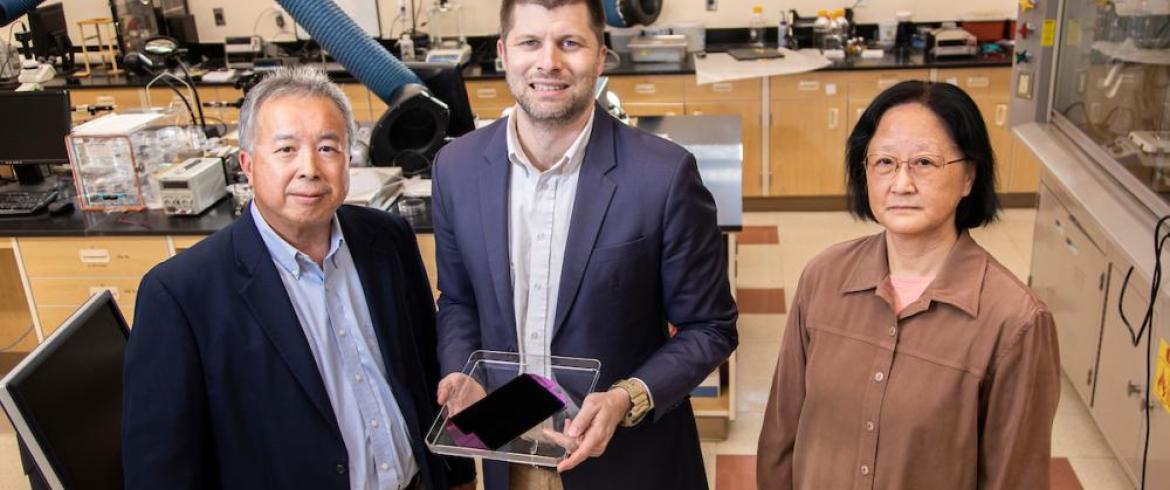

(Left to right): Simon Foo, Ph.D., electrical engineering faculty researcher at the FAMU-FSU College of Engineering; Davis George Moye, founder of Moye Consultants and an alumnus; and Mei Zhang, Ph.D., electrical engineering faculty researcher also at the college, are collaborating to build better graphene-based aircraft batteries for NASA. (M Wallheiser/FAMU-FSU Engineering)

Moye Consultants is partnering with researchers at the FAMU-FSU College of Engineering to make more efficient graphene-based aircraft batteries. The collaboration is part of a NASA initiative to foster partnerships between minority institutions and small businesses.

“For years, NASA has wanted to electrify, or at least partially electrify aviation of all shapes and forms,” Davis George Moye, founder of Moye Consultants said. “By taking the lead, NASA hopes to find low carbon options for industries that historically produce a lot of carbon emissions, such as aviation.”

Florida A&M University’s (FAMU) proposal via the joint college for graphene-based aircraft batteries was one of 11 minority-serving institutions selected for the NASA-Minority Serving Institutions (MSIs) and Small Business Technology Transfer Research (STTR) grant. The projects receive up to $50,000 and last for four months.

Simon Foo, a professor in electrical and computer engineering, and Mei Zhang, a professor in industrial and manufacturing engineering at the FAMU-FSU College of Engineering, are co-principal investigators on the grant. They are working with Moye, who is an alumnus from the college.

Foo and Zhang want to develop a lithium-ion battery (LIB) using graphene-based negative electrodes. The electrodes are synthesized from a graphene nanoribbon material developed by Zhang and other High-Performance Materials Institute (HPMI) researchers. They are also looking at materials that use polyamide-based graphene. The materials have unique properties, which make them ideal for use in batteries for aircraft.

“The material we are testing will enable lithium-ion batteries to exceed the specific energy goals NASA has determined for commercial batteries to make electric aviation a reality,” Foo said. “By employing graphene chemistry into these batteries, we can double or even triple the energy they can store.”

NASA is interested in energy storage for nano-unmanned aerial systems because they require high energy capacity and long cycle life. Other government entities are interested in the technology as well. For example, the U.S. Army uses drones for military missions to protect soldiers’ lives.

Foo explains, “Graphene batteries can provide better chemical stability, higher electrical conductivity, and higher energy capacity, thus allowing for faster cycle times and increased electrode density. They also have the ability to retain the charge longer, improving the lifespan of the battery.”

“In a technical sense, the conductive network formed by graphene can improve the electron and ion transportation of the electrode materials,” Foo said. “This subsequently enhances lithium-ion battery's properties.”

The researchers hope the graphene nanoribbon electrodes will produce batteries with more power by handling high current and will have a longer, maximized cycle life.

Moye’s company provides a software program that tests the materials researchers use to develop batteries. The entrepreneur received his juris doctorate in law from Florida State University (FSU) in 2015 and later came back to finish his Ph.D. in electrical engineering at the FAMU-FSU College of Engineering in 2019.

Moye developed the Simultaneous Battery and Capacitor Design Tool (SiMod) a software program specific to battery and supercapacitor research. He will perform much of the battery design work for the team. His wide range of experience includes experience with the U.S. Navy as the electrical officer on a destroyer. He is currently a commander in the Navy Reserves.

Before founding his company, Moye worked for General Capacitor where he managed $3.5 million in research and development projects to develop lithium-ion capacitor technology. That’s where he learned about the importance of prototyping.

“When I was working at General Capacitor, customers wanted narrowly-tailored energy storage devices for their products,” Moye said. “It took a lot of prototyping to get their product just right. It was a costly, time-consuming process so I developed a computer model that reduced the number of prototypes needed to design of lithium-ion capacitors. After General Capacitor closed, I continued working on the program and started my own company.”

Foo and Zhang will be using the model Moye developed to quantify the performance of the battery. The researchers also use an algorithm Moye Consultants developed to look at the battery’s degradation. Once they have an optimal design, they can prototype this optimal battery design and analyze its specific energy capability.

“FAMU-FSU College of Engineering has patented a processing method for graphene nanoribbons that is cheaper to synthesize and easier to control during fabrication,” Foo said. “We anticipate the graphene nanoribbon-based lithium-ion battery can handle more power than other batteries on the market.”

Small businesses must partner with U.S.-based research institutions to apply for funding from the NASA STTR program. The grant is the first phase in a process that supports collaboration between entrepreneurs and minority-serving research institutions.